Temporary flooring protection for your contract flooring project.

Protection of interior floor finishes is often required on both new and refurbishment projects. Fast track programmes often include floor coverings installed prior to the completion of work by other trades and, to reduce the risk of damage, proper protection materials should be considered.

When you’re looking for Floor Protection, there are many things to take into consideration before choosing which product you will use. We are frequently asked by our customers for advice on which products will provide the best protection in certain working environments.

Choosing the correct floor protection for your needs

There are many forms of temporary protection; a product fit for purpose should be selected after considering the following points:

- Surface requiring protection

- Site conditions and site traffic

- Length of time a surface requires protection prior to handover

It is important that the right form of temporary protection is used, depending on these factors, as an incorrect choice of floor protection may result in poor performance, a need to replace protection more frequently, resulting in higher overall costs as well as adding time to your build, not to mention the possibility of actually damaging the flooring it was originally supposed to protect.

Hard Floors

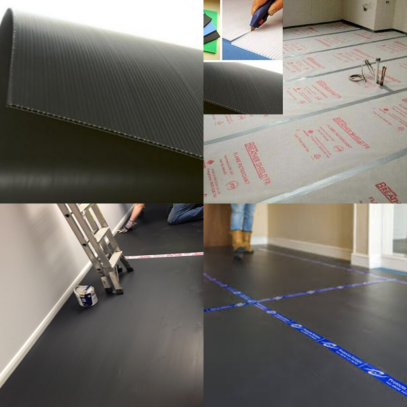

For smooth floors (vinyl, marble, cured timber, laminates, etc.) a certain degree of impact protection is sometimes needed to safeguard any heavy traffic going over it and particularly if tools or equipment are being used as a dropped hammer can easily cause a dent or chip the surface of your floor. There are a various forms of protection that perform well against impact damage and one of the most popular in the construction industry is Plastic corrugated sheet( also called correx, corflute,fluted sheet, coroplast). This is a twin wall/twin fluted polypropylene board that is usually supplied in sheet form, normally 1.2m x 2.4m or 1.2m x 1.8m. The board’s twin wall composition offers a high degree of durability and sturdiness while still being incredibly light in weight meaning it is very easy to handle. This means it is preferable to hardboard alternatives and can also come in recycled form and easily recycled itself therefore being much more environmentally friendly.

Although corrugated plastic protection is fine for use with hardwood floors it has been found on occasions that where high point loads are concerned, for example from access machinery, that timber may become indented with an imprint of the corrugated sheeting. It is advised that on some floor finishes additional protection may be needed to evenly distribute any point loads such as felt or fleece materials or builders cardboard.

Soft Floors

When it comes to soft floors (carpets, etc.) impact protection is not normally an issue. For cut-pile carpets a self-adhesive carpet protector can be used, which is supplied in various sizes. This product is simply rolled out and sticks directly to the carpet without the need for additional fixing to hold it in place. The ‘tacky back’ will hold the product in place during the programme of works. After use the material simply peels clean, leaving no residue. With products such as these the general recommendation is that they aren’t left in place longer than 4 weeks as any longer may risk residue being left on the carpet.

For loop and cut pile carpets or protection for carpets for a much longer period of time, a loose fitting membrane can be used, either a polypropylene or polyethylene sheeting. This can then be fixed in place using either tapes, or, for a loop pile carpet using a male Velcro dry fix method.

Moisture-sensitive Flooring and Screed

If you are working with moisture-sensitive flooring such as uncured timber then there can be issues if protected for prolonged periods with impervious protection material as there is a chance that the floor may ‘sweat’ underneath. This is of particular relevance where there is under floor heating. If impervious protection is to be used long term over a moisture sensitive floor covering it is advisable to contact the manufacturers of the flooring beforehand as a build-up of moisture between the floor and the protection may cause damage. It is advisable with these types of floors that instead of an impervious material being used for protection that a ‘breathable’ material is used instead.

Post time: Aug-06-2020